A jaw crusher production line, also known as a stone crushing plant or aggregate production line, is an integrated system of machines designed to crush large rocks and raw materials into smaller, specified sizes for various applications like construction, road building, and concrete production.

The jaw crusher serves as the primary crusher in this line, meaning it performs the first and most heavy-duty stage of crushing.

The configuration follows the logical flow of material from large to small. Here are the essential components in order of operation:

1. Feeding Stage

Hopper: A large, funnel-shaped container where raw material (like blasted rock from a quarry) is initially loaded by excavators or loaders. It acts as a temporary storage buffer.

Vibrating Feeder (or Grizzly Feeder): This is a critical piece of equipment positioned beneath the hopper. Its functions are twofold:

Regulates Flow: It uses vibration to provide a steady, controlled flow of material into the jaw crusher. This prevents the crusher from being overloaded (choked) or under-fed (running empty), ensuring maximum efficiency.

Pre-Screening (Grizzly): Many feeders have a "grizzly" section with parallel bars. This allows smaller rocks and soil that don't need primary crushing to bypass the jaw crusher, reducing wear and tear and increasing overall capacity. This fine material is collected on a conveyor belt below.

2. Primary Crushing Stage

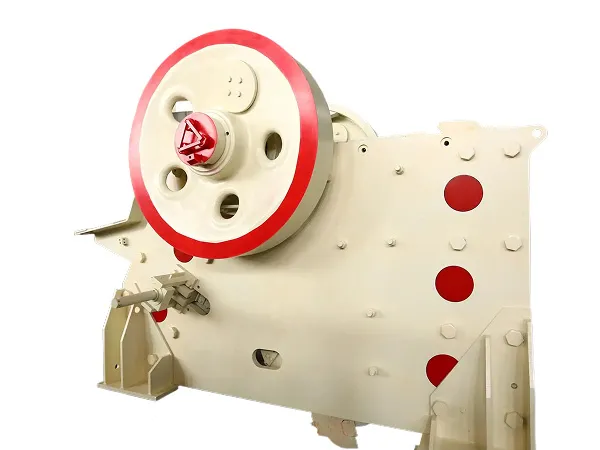

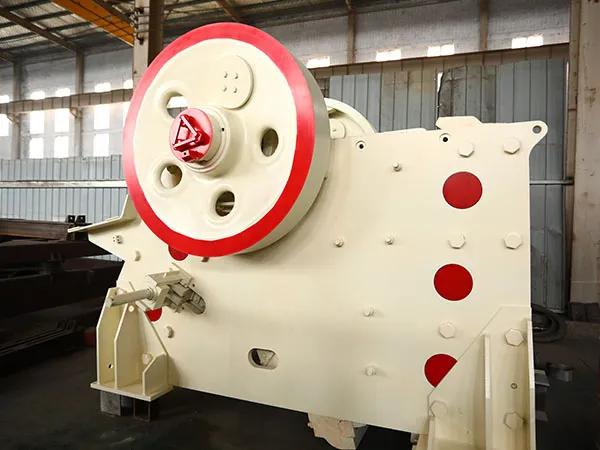

Jaw Crusher: This is the heart of the primary stage. It crushes large rocks through compression. A fixed jaw plate and a moving (swing) jaw plate form a V-shaped crushing chamber. The moving jaw applies immense force, breaking the rock as it moves down the chamber until it is small enough to pass through the discharge opening at the bottom.

3. Conveying Stage

Conveyor Belts: These are the arteries of the production line. A main conveyor belt transports the crushed material from the jaw crusher to the next stage. A network of conveyors moves material between all subsequent machines and finally to the stockpiles.

4. Screening & Separation Stage

Vibrating Screen: This is a large sieve that sorts the material by size. The crushed rock from the jaw crusher is dropped onto a multi-layered, vibrating screen.

Oversized Material: Rocks that are still too large are sent to the secondary crusher for further reduction.

Finished Product: Material that meets the required size specification is separated out and sent to a stockpile via a conveyor.

Fine Material: Smaller particles may be sent to another screen for further classification or to a tertiary crushing stage if sand production is required.

5. Secondary & Tertiary Crushing Stage (Optional but Common)

Secondary Crusher: Since the jaw crusher only performs coarse crushing, a secondary crusher is needed to achieve finer sizes. The type depends on the rock hardness and desired product shape:

Cone Crusher: Ideal for hard, abrasive materials like granite, basalt, and river stone. It uses compression and produces well-shaped, cubical aggregate.

Impact Crusher: Best for softer to medium-hard materials like limestone and dolomite. It uses high-speed impact force, which creates a high percentage of fine material and excellent cubical shape.

Tertiary Crusher (e.g., VSI Crusher): For producing fine aggregate or manufactured sand, a third stage of crushing is often required. A Vertical Shaft Impactor (VSI) is commonly used. It throws rocks against an anvil at high speed, causing them to shatter. This is excellent for shaping and creating sand.

6. Final Product Stage

Final Vibrating Screen: After secondary/tertiary crushing, the material is sent back to another screen to be sorted into final product sizes (e.g., 0-5mm, 5-10mm, 10-20mm).

Stockpiles: Conveyor belts move the finished, sorted aggregates to designated stockpiles, ready for transport.

A full production line also includes essential support systems:

Dust Suppression System: Sprays water mist at key points (crushers, transfer points) to control airborne dust, which is crucial for environmental compliance and worker safety.

Centralized Electric Control System: A control cabinet or room with PLCs (Programmable Logic Controllers) to start, stop, and monitor all the equipment in the line, ensuring proper sequencing and safety.

Magnetic Separator: Often placed over a conveyor belt to remove any tramp metal (like steel from excavation equipment) before it can damage downstream crushers, especially cone or impact crushers.

The exact configuration depends heavily on the raw material, the desired output sizes, and the required capacity (tons per hour).

Example 1: Basic Two-Stage Crushing Line (for Hard Rock)

Flow: Vibrating Feeder → Jaw Crusher (Primary) → Vibrating Screen → Cone Crusher (Secondary) → Final Vibrating Screen → Final Products.

Application: Standard aggregate production for concrete and asphalt from hard rock like granite.

Example 2: Three-Stage Crushing & Sand Making Line

Flow: Vibrating Feeder → Jaw Crusher (Primary) → Impact Crusher (Secondary) → Vibrating Screen → VSI Crusher (Tertiary/Sand Maker) → Final Vibrating Screen → Final Products (Aggregates + Manufactured Sand).

Application: High-quality aggregate and manufactured sand production for high-spec concrete and infrastructure projects.

Example 3: Mobile Crushing Plant

The entire sequence of machines (feeder, jaw crusher, screen, conveyors) is mounted on a single wheeled or tracked chassis. This provides flexibility for contractors who move between job sites. Multiple mobile units (e.g., a mobile jaw crusher followed by a mobile cone crusher/screen) can be linked to create a full production line.

In summary, a jaw crusher is the starting point and primary workhorse of a crushing line. Its configuration with feeders, screens, secondary crushers, and conveyors creates a complete system that transforms massive, unusable rock into valuable, precisely-sized construction materials.

Complete Guide to Sand Washing Machines: Working Principle and Industrial Sand Cleaning

2026-01-28 00:58How to Adjust Water Flow in a Sand Washing Machine: A Comprehensive Practical Guide

2026-01-23 01:29Sand Washing Machine Installation Guide: Step-by-Step Instructions for Optimal Performance

2026-01-15 06:46How Much Does a Sand Washing Machine Cost? A Practical Buyer’s Guide for 2026

2026-01-09 04:37Address: Luoyang Luoxin Industrial Park, Henan,China

E-mail: sales@yd-crusher.com

Phone: 86-139-3993-0123

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China