High-quality industrial sand is essential in construction, concrete production, glass manufacturing, and foundries. However, raw sand from rivers, quarries, or mines often contains impurities such as clay, silt, dust, and organic matter. To meet industry standards, sand must be cleaned efficiently—this is where sand washing machines come in.

This guide explains the types, working principles, industrial cleaning processes, and selection tips for sand washing machines, helping manufacturers improve sand quality, reduce labor, and ensure environmental compliance.

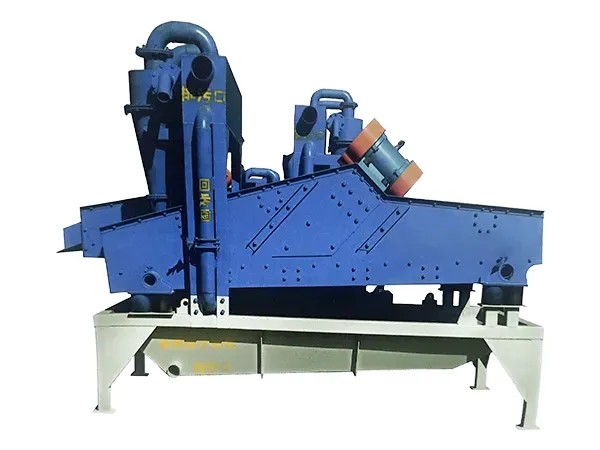

A sand washing machine is a device used to remove impurities and improve the quality of industrial sand. By washing away mud, dust, and light debris, it produces clean, uniform sand suitable for concrete, mortar, or other industrial uses.

Common Types of Sand Washing Machines

Wheel Sand Washer

Uses a rotating wheel to lift sand while water washes off impurities.

Ideal for medium to coarse sand.

Spiral Sand Washer

Employs a slow-rotating spiral to stir sand in water, separating mud and silt.

Suitable for fine sand and continuous operation.

Rotary Drum Sand Washer

Rotating drum scrubs and separates sand from water.

Ideal for large-scale industrial sand processing.

Logwasher (Clay Removal)

Scrapes and agitates sticky sand to remove clay and heavy mud.

Commonly used in mining and high-clay-content sand.

The basic principle is consistent: mechanical agitation and water flow remove impurities from sand.

a) Wheel Sand Washer

Sand is fed into a water tank.

Rotating wheels lift and wash the sand.

Mud and silt exit via overflow or drainage, while clean sand is discharged.

Best for coarse sand with moderate clay content.

b) Spiral Sand Washer

Sand enters a water-filled spiral tank.

Spiral blades rotate slowly, mixing sand and water.

Fine particles, mud, and impurities are washed away.

Clean sand is lifted and discharged from the spiral outlet.

Efficient for fine sand, saves water, and supports continuous operation.

Industrial sand cleaning often involves multiple stages to ensure high purity:

Screening – Removes large stones or debris with a vibrating screen.

Washing – Sand washing machines remove clay, silt, and light impurities.

Classification (Optional) – Hydrocyclones or classifiers separate sand by particle size.

Dewatering – Screw dewatering machines or vibrating screens remove excess water.

Wastewater Management – Muddy water is collected and treated, reducing environmental impact.

Construction – Produces clean sand for concrete, mortar, and road construction.

Glass Manufacturing – Ensures silica sand purity for high-quality glass.

Foundries – Provides molding sand for precision casting.

Industrial Minerals – Cleans quartz, feldspar, and other minerals for industrial use.

Improves sand cleanliness and particle uniformity.

Removes clay, dust, and organic impurities.

Enhances concrete strength and durability.

Reduces labor costs and manual cleaning.

Helps manage wastewater and meet environmental regulations.

Supports integration with screening, dewatering, and slurry recovery systems.

Production Capacity – Choose according to daily sand output.

Sand Type – Wheel washers suit coarse sand; spiral washers are better for fine sand.

Water Availability – Spiral washers consume less water.

Maintenance – Simple, robust designs reduce downtime.

Production Line Compatibility – Ensure the machine works well with screening, dewatering, and slurry recovery systems.

Sand washing machines are essential for industrial sand processing. By combining washing, classification, dewatering, and wastewater management, manufacturers can produce high-quality sand, increase efficiency, reduce costs, and meet environmental standards. Selecting the right sand washing machine ensures clean, uniform sand suitable for construction, glass, foundry, and industrial mineral applications.

Complete Guide to Sand Washing Machines: Working Principle and Industrial Sand Cleaning

2026-01-28 00:58How to Adjust Water Flow in a Sand Washing Machine: A Comprehensive Practical Guide

2026-01-23 01:29Sand Washing Machine Installation Guide: Step-by-Step Instructions for Optimal Performance

2026-01-15 06:46How Much Does a Sand Washing Machine Cost? A Practical Buyer’s Guide for 2026

2026-01-09 04:37Address: Luoyang Luoxin Industrial Park, Henan,China

E-mail: sales@yd-crusher.com

Phone: 86-139-3993-0123

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China