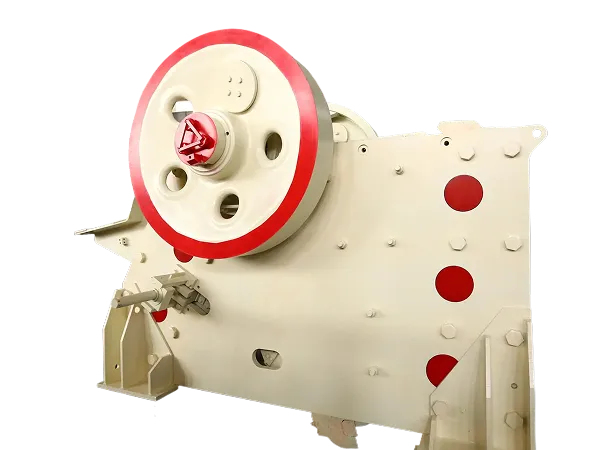

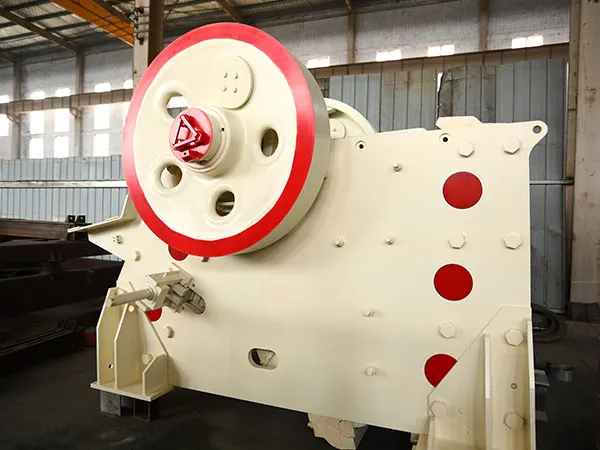

Choosing the right jaw crusher model is a critical decision that can significantly impact the efficiency and profitability of your operation. A well-suited crusher will handle your material effectively, meet your production targets, and require less maintenance over time. Conversely, a poor choice can lead to bottlenecks, excessive wear, and increased operating costs.

1. Material Characteristics

Hardness and Abrasiveness: This is arguably the most important factor. Hard and abrasive materials like granite, basalt, and certain ores require a crusher with a robust structure and high-quality, wear-resistant components (e.g., high manganese steel jaw plates). Softer materials like limestone or asphalt can be processed by crushers with lower power and less-durable components.

Feed Size and Shape: You need to measure the maximum size of the material you will be feeding into the crusher. The feed opening of the jaw crusher must be large enough to accommodate this material without causing jams or bridging. A good rule of thumb is that the maximum feed size should be no more than 80% of the crusher's feed opening.

Moisture Content: Materials with high moisture content can be sticky and prone to clogging the crushing chamber. If you are dealing with wet or sticky materials, you should select a crusher with a larger discharge opening and a design that facilitates good drainage to prevent operational issues.

2. Production Requirements

Required Capacity: Crushers are rated by their output in tons per hour (TPH). You need to determine your desired production volume and choose a model with a capacity that can meet or exceed your targets. Underpowered crushers will create bottlenecks in your production line.

Desired Output Size: Jaw crushers are primarily for rough size reduction (primary crushing). They produce a coarse, angular, and less uniform product. The final product size is determined by the "closed-side setting" (CSS), which is the gap between the jaw plates at their closest point. Most jaw crushers are not suitable for producing very fine fractions and are often followed by a secondary crusher (like a cone or impact crusher) to achieve the final desired particle size.

3. Operational and Maintenance Considerations

Crushing Stage: Jaw crushers are typically used for primary crushing, taking large, raw feed and breaking it down into smaller, manageable sizes. If you need a more uniform, cubical product or finer fractions, you will need to plan for a secondary or tertiary crusher as part of your overall crushing circuit.

Durability and Maintenance: Look for crushers made with high-quality steel and durable components. Consider the ease of maintenance—how simple is it to access and replace wear parts like jaw plates and bearings? Models with a hydraulic adjustment system for the closed-side setting are often easier and quicker to operate than those that require manual shims.

Power and Energy Efficiency: The motor size must be sufficient to handle the crushing load. Consider the energy consumption of the crusher, as an energy-efficient model can lead to significant savings in operating costs over its lifespan.

Mobility: Decide if you need a stationary or mobile crusher. Stationary plants are for long-term, high-volume operations, while mobile (track-mounted or skid-mounted) crushers offer flexibility and are ideal for projects that move from site to site.

4. Cost and Support

Total Cost of Ownership: Don't just focus on the initial purchase price. Factor in the total cost of ownership, including operating costs (power, fuel, etc.), maintenance, and replacement parts.

Manufacturer Reputation and Support: Research the manufacturer's reputation for quality, reliability, and after-sales support. A reputable manufacturer will provide reliable technical support, training, and a readily available supply of replacement parts.

Undersizing the Crusher: The most common mistake. Trying to save money upfront by buying a smaller crusher leads to it being a production bottleneck for its entire life.

Ignoring Material Stickiness: Choosing a standard crusher for high-clay material will result in constant clogging and downtime.

Focusing Only on Purchase Price: Ignoring TCO can lead to buying a machine that costs far more in the long run due to high wear, poor efficiency, and frequent breakdowns.

Not Considering the Entire Circuit: The jaw crusher is just one part. It must be matched with an appropriate feeder (like a vibrating grizzly feeder) to ensure a controlled and continuous feed.

By carefully evaluating these factors, you can make an informed decision and select a jaw crusher model that is a good fit for your specific application and business needs.

Complete Guide to Sand Washing Machines: Working Principle and Industrial Sand Cleaning

2026-01-28 00:58How to Adjust Water Flow in a Sand Washing Machine: A Comprehensive Practical Guide

2026-01-23 01:29Sand Washing Machine Installation Guide: Step-by-Step Instructions for Optimal Performance

2026-01-15 06:46How Much Does a Sand Washing Machine Cost? A Practical Buyer’s Guide for 2026

2026-01-09 04:37Address: Luoyang Luoxin Industrial Park, Henan,China

E-mail: sales@yd-crusher.com

Phone: 86-139-3993-0123

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China