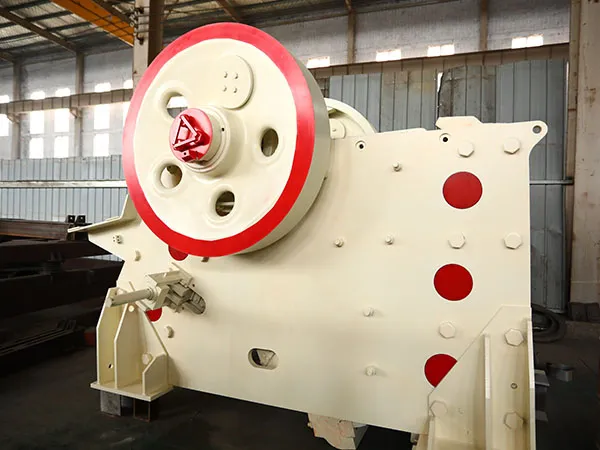

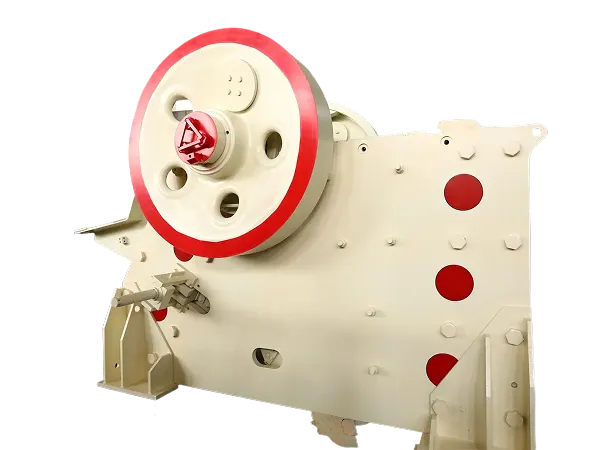

Jaw crushers are the workhorses of the crushing world, primarily designed for breaking down hard, abrasive, and tough materials. They are almost always used as primary crushers, meaning they take the largest, run-of-mine or run-of-quarry rock and break it into a more manageable size for secondary crushers.

Here is a breakdown of the main materials jaw crushers are used to crush, grouped by industry:

1. Quarrying and Construction Aggregates

This is the most common application. Jaw crushers are essential for producing the stone used in roads, buildings, and other infrastructure projects.

Granite: Extremely hard and abrasive, a classic material for a jaw crusher.

Basalt: A hard, dense volcanic rock used extensively in asphalt and concrete.

Gabbro & Diorite: Similar hard igneous rocks.

Quartzite: One of the hardest and most abrasive rocks, which jaw crushers are specifically built to handle.

Limestone & Dolomite: While less hard than granite, jaw crushers are frequently used as the primary breaker for large quarried blocks.

River Stone / Gravel: Hard, rounded, and often abrasive natural aggregates.

2. Mining Operations

In mining, the jaw crusher is the first step in comminution—the process of reducing the size of ore to liberate the valuable minerals from the waste rock.

Iron Ore: Crushing large chunks of ore like hematite and magnetite.

Copper Ore: Breaking down ores such as chalcopyrite and bornite.

Gold Ore: The initial crushing of hard rock ore before it goes to grinding mills.

Bauxite (Aluminum Ore): The primary crushing stage in aluminum production.Lead, Zinc, and Nickel Ores: Any hard rock ore that needs to be broken down for mineral processing.

3. Recycling

The recycling industry relies heavily on the power and durability of jaw crushers to process tough, man-made materials.

Recycled Concrete: Crushing demolished concrete slabs and structures. Jaw crushers are excellent at handling the embedded steel rebar, which is typically separated out later by magnets.

Asphalt Pavement: Breaking up large chunks of reclaimed asphalt (RAP) for reuse in new pavement mixes.

Bricks and Demolition Debris (C&D Waste): Reducing mixed construction waste into a usable recycled aggregate.

To summarize, jaw crushers are ideal for materials that are:

High in Compressive Strength: They excel at breaking materials that resist being squeezed.

Hard and Abrasive: Their replaceable manganese steel jaw plates (wear parts) are designed to withstand the intense wear from materials like quartz and granite.

Dry and Non-Sticky: They work best on materials that will not pack or clog the crushing chamber.

It's also helpful to know what they are not used for:

Sticky or Clay-like Materials: Wet clay or soil can pack the crushing chamber, a phenomenon known as "packing" or "blinding," which stops the crushing process.

Soft, Friable Materials: For softer materials like coal or shale, an impact crusher is often more efficient and produces a better-shaped final product with fewer fines.

Scrap Metal: While they can handle rebar within concrete, they are not designed to crush large, standalone pieces of metal, which can cause severe damage.

Elastic Materials: Materials like rubber or wood will not fracture under compression and will jam the machine.

Jaw crushers are primarily used to crush hard, large, and abrasive materials. They act as primary crushers, taking in big chunks of raw material and breaking them down into smaller, more manageable sizes for further processing.

In essence, if you have large, hard, blocky material that needs a powerful compressive force to be broken down, the jaw crusher is the go-to machine for the job.

Complete Guide to Sand Washing Machines: Working Principle and Industrial Sand Cleaning

2026-01-28 00:58How to Adjust Water Flow in a Sand Washing Machine: A Comprehensive Practical Guide

2026-01-23 01:29Sand Washing Machine Installation Guide: Step-by-Step Instructions for Optimal Performance

2026-01-15 06:46How Much Does a Sand Washing Machine Cost? A Practical Buyer’s Guide for 2026

2026-01-09 04:37Address: Luoyang Luoxin Industrial Park, Henan,China

E-mail: sales@yd-crusher.com

Phone: 86-139-3993-0123

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China