A sand washing machine is a cornerstone in the sand and gravel industry, responsible for producing clean, high-quality sand by removing impurities such as clay, silt, and dust. Correct installation is not just a technical requirement—it directly impacts machine efficiency, durability, and long-term production costs. In this detailed guide, we walk you through each stage of installation, offering practical tips, common pitfalls to avoid, and best practices for achieving optimal performance.

Before the machine arrives, thorough site preparation is essential to prevent operational issues later.

Level and Stable Foundation:

The ground must be flat, compact, and reinforced. For heavy-duty sand washing machines, a reinforced concrete foundation is recommended to withstand vibration and load.

Uneven surfaces can lead to misalignment, accelerated wear, and even mechanical failure.

Drainage Considerations:

Ensure the site has effective drainage. Standing water can damage electrical components and reduce washing efficiency.

Consider installing a sloped foundation that guides wastewater to a dedicated drainage system.

Accessibility for Operation and Maintenance:

Leave enough clearance around the machine for installation, routine maintenance, and emergency access.

A 1–2 meter clearance around the machine is generally recommended for most industrial models.

Pro Tip: Take photos of the prepared site before installation. It helps during assembly and troubleshooting.

When the machine arrives, careful inspection can prevent costly downtime later.

Unpack all components systematically and check for visible shipping damage.

Use the equipment checklist from the manual to confirm that all parts—motors, belts, bolts, and washing wheels—are included.

Inspect belts, screws, electrical connections, and the washing impeller for cracks, dents, or deformation.

Document any issues immediately with the supplier to avoid warranty disputes.

Insider Tip: Even minor scratches or loose bolts should be corrected before assembly. Small oversights can escalate into major mechanical problems.

Assembly may vary depending on the model, but most sand washing machines follow a similar setup sequence:

Mount the Frame and Tank:

Position the main frame on the prepared foundation.

Use anchor bolts to secure the frame firmly, ensuring zero wobble.

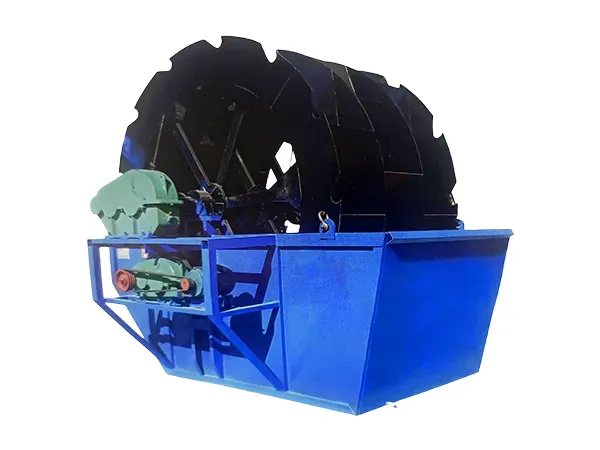

Install the Washing Wheel or Spiral:

Ensure the impeller rotates freely without touching the tank walls.

Misalignment here can reduce washing efficiency and cause premature wear.

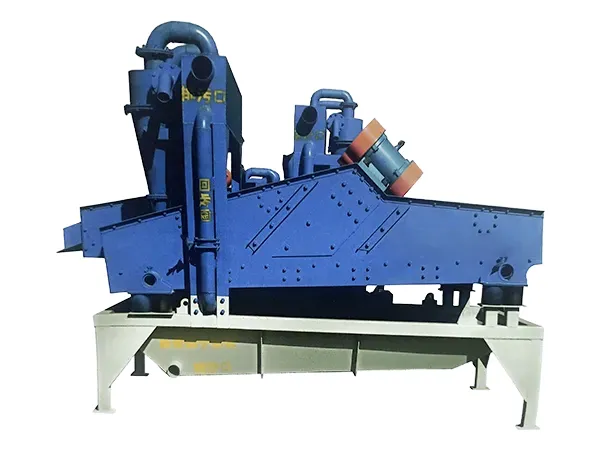

Connect Motor and Drive System:

Check belt tension and alignment carefully. Belts should not be too tight or loose.

Improper alignment may produce vibration, reduce efficiency, or damage bearings.

Attach Water Pipes:

Connect inlet and outlet pipes, checking for watertight seals.

Consider using flexible joints to absorb vibrations and prevent pipe stress.

Pro Tip: Label all electrical and hydraulic connections during assembly. It makes future maintenance much faster.

Proper leveling is critical for efficiency and longevity.

Use a spirit level or laser level to verify horizontal alignment.

Adjust foundation bolts or add shims if needed.

Ensure the impeller or spiral is perfectly centered to prevent wobbling and uneven wear.

Quick Check: After leveling, rotate the impeller by hand to ensure it moves smoothly without touching the tank.

Electrical Setup:

Follow the manufacturer’s wiring diagram exactly.

Confirm voltage and frequency compatibility.

Ensure proper grounding to prevent electrical hazards.

Water Supply:

Check inlet water pressure; too low pressure reduces washing efficiency, too high may damage the system.

Install filters to prevent sand or debris from entering the water system.

Pro Tip: Use waterproof connectors for outdoor installations to reduce corrosion risks.

Before processing real sand, conduct a trial run:

Fill the tank with water and operate the machine empty to observe rotation and detect unusual noise or vibration.

Inspect belts, bearings, and seals for leaks or overheating.

Gradually add sand and monitor washing efficiency, water flow, and discharge quality.

Adjust rotation speed, water volume, or tank incline as needed to achieve optimal sand cleaning.

Insider Advice: Document your initial settings—they serve as a reference for seasonal adjustments or when processing different sand types.

Routine maintenance protects your investment and ensures continuous high-quality output:

Daily Checks:

Inspect bearings, belts, motor, and tank for debris accumulation.

Remove any residual sand that may cause abrasion.

Lubrication:

Follow the manufacturer’s recommended schedule. Proper lubrication extends motor and bearing life.

Periodic Inspections:

Examine structural components, anchor bolts, and welding seams.

Tighten loose bolts and replace worn parts promptly.

Pro Tip: Keep a maintenance log. Tracking inspections and repairs helps predict potential failures before they happen.

Conclusion

Proper installation of a sand washing machine is more than just following instructions—it’s about attention to detail at every stage. From site preparation to trial runs and routine maintenance, each step plays a crucial role in achieving consistent, high-quality sand output. By following this comprehensive guide, operators can maximize efficiency, extend equipment life, and reduce unexpected downtime. A well-installed sand washing machine doesn’t just clean sand—it ensures your operation runs smoothly and profitably.

Impact Crusher Price Guide: Understanding the Real Factors Behind Your Investment Costs

2026-02-25 01:28Complete Guide to Sand Washing Machines: Working Principle and Industrial Sand Cleaning

2026-01-28 00:58How to Adjust Water Flow in a Sand Washing Machine: A Comprehensive Practical Guide

2026-01-23 01:29Sand Washing Machine Installation Guide: Step-by-Step Instructions for Optimal Performance

2026-01-15 06:46Address: Luoyang Luoxin Industrial Park, Henan,China

E-mail: sales@yd-crusher.com

Phone: 86-139-3993-0123

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China