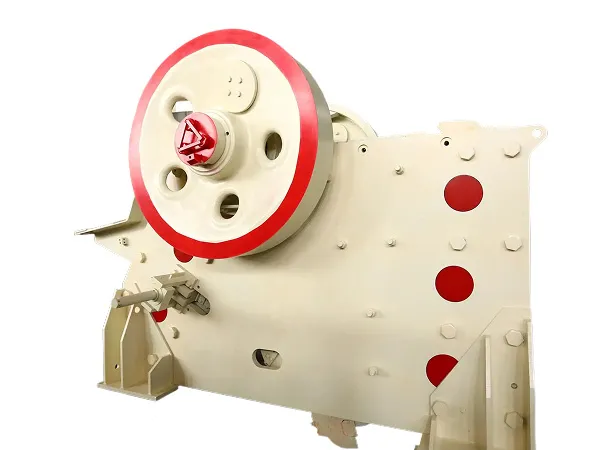

Jaw crushers are widely used in industries such as mining, aggregate production, and construction waste recycling due to their robust structure, high crushing efficiency, and wide adaptability. However, selecting the right model for different material hardness, moisture content, particle size, and output requirements is not easy. This article provides a practical and systematic jaw crusher selection guide to help you avoid selection errors, improve production efficiency, and reduce operating costs.

1. Common Models and Features

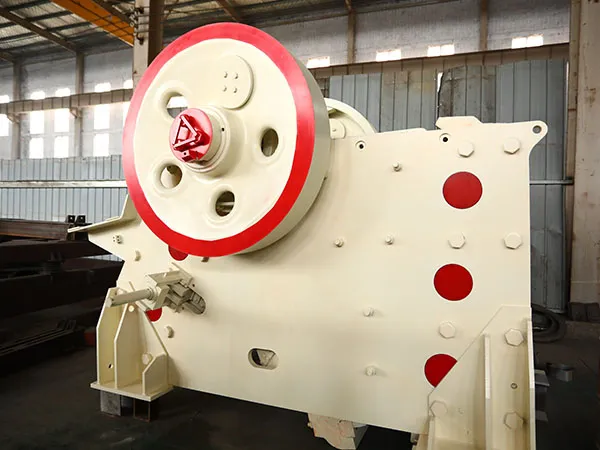

Stationary Jaw Crusher: Suitable for long-term fixed sites such as mines and aggregate plants, offering high output and stable operation.

Mobile Jaw Crusher: Equipped with a tracked or wheeled chassis, allowing for flexible movement and suitable for construction waste processing or multi-site construction.

Single Toggle Jaw Crusher: High crushing efficiency, simple structure, and low maintenance cost.

Double Toggle Jaw Crusher: Uniform force distribution in the crushing chamber, suitable for ultra-hard materials, stable operation but more complex maintenance.

2. Working Principle and Applicable Scenarios

Jaw crushers use the periodic compression of fixed and movable jaw plates to crush large pieces of ore into the required particle size. Main applications include:

Coarse crushing of raw ore

Crushing of construction waste

Materials with compressive strength ≤320MPa, such as various ores, limestone, and granite.

1. Hardness matching

|

Material hardness |

Typical materials |

Recommended models |

|

soft |

limestone, coal |

Single pendulum type, small and medium-sized jaw crusher |

|

Medium hard |

Iron ore, basalt |

Heavy-duty single or double pendulum |

|

Super hard |

Quartzite, granite |

Double-pendulum large heavy-duty aircraft |

Note: Lightweight or small mobile machines are not suitable for handling extremely hard materials, as this may accelerate wear.

2. Moisture and Viscosity

High-moisture/viscous materials (sludge, wet sand): Utilize an anti-clogging chamber design, equipped with a vibrating feeder and screening device.

Low-moisture dry materials: A standard crushing chamber is sufficient.

3. Particle Size and Output

Large feed (≥500mm): A large-aperture jaw crusher is preferred.

Fine crushing requirements (≤80mm): Use a fine jaw crusher or a two-stage cone/impact crusher combination.

High output (≥500t/h): Stationary heavy-duty models offer greater stability.

|

Operating environment |

Applicable models |

Features |

|

Heavy mining quarries |

Fixed heavy-duty jaw crusher (double pendulum optional) |

High reliability, suitable for hard rock, continuous high-load operation |

|

Construction waste recycling |

Mobile jaw crusher |

Mobile operation reduces transportation costs |

|

Continuous high-load production |

Fixed type + large capacity flywheel |

Stable output, reduced energy consumption |

|

Intermittent work |

Small and medium-sized pendulum or mobile units |

Easy to start and stop, high cost performance |

|

Multi-condition switching |

Tracked mobile jaw crusher |

Flexible deployment and rapid switching of work scenarios |

Initial Investment vs. Long-Term Operation and Maintenance

Mobile Units: Higher purchase cost, but saves on infrastructure and transportation costs.

Stationary Units: Lower equipment cost, but require additional foundation construction costs.

Spare Parts Lifespan and Maintenance Ease

High-wear-resistant jaw plates extend service life and reduce maintenance costs.

Single-pendulum models have a simple structure and are quick to repair.

Choosing globally sourced spare parts brands reduces downtime.

Energy Saving and Efficiency Optimization

Variable frequency drive reduces idle energy consumption.

Deep cavity crushing design increases crushing efficiency by 20%–30%.

Properly integrated vibrating feeder prevents material blockage and increases production capacity.

Quick Selection Steps

Identify Material Type and Hardness (Soft/Medium-Hard/Hard Rock)

Measure Maximum Feed Size

Determine Required Output (t/h)

Identify Operating Scenario (Mine/Construction Waste/Mobile Operation)

Evaluate Budget and Long-Term Maintenance Costs

Confirm Power Supply, Site, and Foundation Conditions

Choose a Manufacturer with Project Cases and Comprehensive After-Sales Service

Q: The material is very hard, can a jaw crusher be used?

A: Yes, but a double-pendulum heavy-duty model or high-wear-resistant jaw plates is recommended to avoid rapid wear.

Q: Will the output of a mobile jaw crusher be lower than that of a stationary one?

A: Stationary crushers generally have higher output, but mobile crushers offer greater flexibility and can save on transportation costs, resulting in significant overall benefits.

Q: Why do wet materials easily clog?

A: Wet materials have strong adhesion, requiring an anti-clogging cavity design and matching screening equipment.

Choosing the right jaw crusher not only improves crushing efficiency but also directly affects operating costs and production stability. The operating condition analysis and selection guide provided in this article allows you to accurately match equipment and ensure efficient project operation. If you wish to customize a crushing solution based on material characteristics and output, we offer free operating condition analysis services to help your company achieve more efficient production management.

How to Replace Cone Crusher Bronze Bushings Correctly: A Complete Step-by-Step Guide

2026-03-05 04:48Impact Crusher Price Guide: Understanding the Real Factors Behind Your Investment Costs

2026-02-25 01:28Complete Guide to Sand Washing Machines: Working Principle and Industrial Sand Cleaning

2026-01-28 00:58How to Adjust Water Flow in a Sand Washing Machine: A Comprehensive Practical Guide

2026-01-23 01:29Address: Luoyang Luoxin Industrial Park, Henan,China

E-mail: sales@yd-crusher.com

Phone: 86-139-3993-0123

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China