In the stone crushing industry, the jaw crusher plays an irreplaceable role. For many sand and gravel plants, improving overall capacity, reducing energy consumption, and achieving stable finished product particle size all rely on optimizing jaw crusher performance and improving usage strategies. This article will break down how jaw crushers help stone crushing plants significantly improve efficiency, from working principles and efficiency determinants to real-world application cases and solutions to common problems.

Jaw crushers are mainly used in the primary crushing stage of the stone crushing process, compressing large pieces of ore or stone into small to medium particle sizes suitable for subsequent secondary crushing.

● Brief Description of Working Principle

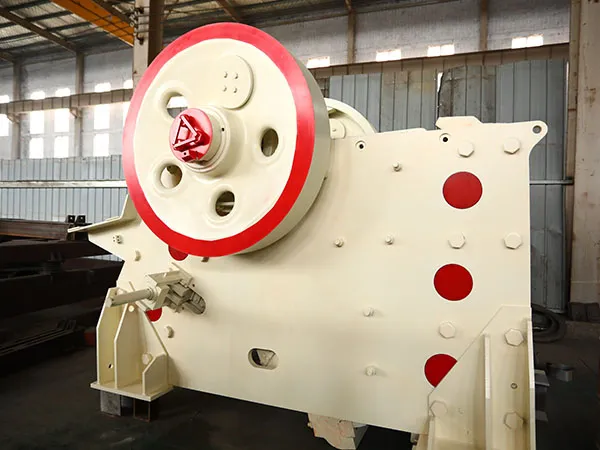

The jaw crusher gradually crushes large pieces of material through repeated squeezing and compression between the fixed jaw plate and the moving jaw plate. The motor drives the pulley and eccentric shaft, causing the moving jaw to periodically approach and move away from the fixed jaw, thus completing the continuous crushing process.

● Importance of Primary Crushing

The efficiency of primary crushing directly determines the output and stability of the entire production line.

The more stable the crushed particle size, the higher the efficiency of downstream equipment (impact crusher, cone crusher, sand making machine);

Jaw crushers can stabilize stone flow, improve crushing efficiency, and reduce the risk of blockage;

With its large crushing ratio and low operating cost, it is the preferred primary crushing equipment for most sand and gravel plants.

The output and operating efficiency of a jaw crusher are affected by a variety of factors. The following are the four most crucial aspects.

1. High Crushing Ratio and Large Processing Capacity

Highly Efficient Working Principle: Jaw crushers crush materials using compression, splitting, and bending methods. The material is repeatedly compressed between the moving and fixed jaws, achieving highly efficient crushing.

Ideal Choice for Primary Crushing: Jaw crushers are typically used as the first step in a crushing production line (primary crushing). They can handle large-particle-size, high-hardness materials, directly crushing large ore or rocks to medium particle size, providing suitable feed size for subsequent secondary and tertiary crushing processes (such as cone crushers and impact crushers), thereby reducing the load on subsequent equipment.

Continuous Production: Modern jaw crushers are designed with large feed openings and deep cavities, ensuring smooth material entry and crushing, guaranteeing the continuity and stability of the production line.

2. Structural Design Optimizes Production Efficiency

Adjustable Discharge Opening: By adjusting the discharge opening size, the particle size range of the product can be flexibly controlled to meet the requirements of different customers or subsequent processes. Precise particle size control helps reduce over-crushing, improving finished product quality and efficiency.

Streamlined Process: Some large jaw crushers can directly crush large stones to near the final product particle size, reducing the number of crushing stages and thus simplifying the entire crushing process.

Easy Replacement of Wear Parts: Wear parts such as jaw plates are designed for quick replacement, shortening maintenance and downtime and improving the actual operating efficiency of the equipment.

3. Operational Stability and Maintenance Advantages

Robust and Durable: Jaw crushers have a simple, robust, and reliable structure, making them particularly suitable for handling hard and highly abrasive materials, with a relatively low failure rate.

Overload Protection: They are typically equipped with safety devices (such as toggle plates) to protect major components from damage when uncrushable objects enter, ensuring long-term stable operation of the equipment.

High Adaptability: Jaw crushers are highly adaptable to changes in the moisture content and mud content of stone, are less prone to clogging, and ensure continuous production.

4. Key to Improving the Overall Efficiency of a Crushing Plant

Optimized Crushing Process: The overall efficiency of a stone crushing plant depends not only on the efficiency of individual machines but also on the configuration of the entire crushing system. Jaw crushers, as the "main force," ensure the smooth operation of subsequent processes (such as screening, conveying, and secondary crushing) through stable and efficient performance.

Reducing operating costs: Excellent jaw crushers feature relatively reasonable energy consumption and long wear parts life, which helps reduce production and operating costs, thereby economically improving factory efficiency.

A medium-sized sand and gravel plant experienced the following problems after using a jaw crusher for one year:

Significantly decreased output

Increased frequency of cone crusher blockage

Increased energy consumption

The plant improved jaw crusher performance through the following optimization measures:

Adjusted the discharge opening from 120mm to 140mm

Optimized the moving jaw speed

Weekly equipment inspections and monthly system maintenance

Replaced severely worn jaw plates

Final Results:

Daily output increased by 18% (jaw crusher throughput increase)

Energy consumption decreased by 12%

Downstream blockage rate decreased by 40%

This case study verifies that scientific calibration and maintenance are the most effective means of improving jaw crusher productivity.

Problem 1: Jaw Crusher Blockage

Solution:

Control feed size

Stable feed rate

Handle materials with high mud content

Regularly clean the crushing chamber

Problem 2: Jaw Crusher Capacity Fluctuation

Inspection Items:

Is the feeder malfunctioning?

Is the jaw plate severely worn?

Is the discharge port too small?

Is the motor power stable?

Problem 3: High Jaw Crusher Energy Consumption

Common Causes:

Insufficient bearing lubrication

Severe jaw plate wear

Equipment operating at full load or overload

Improper moving jaw trajectory settings

Solution: Optimize parameters + Enhance maintenance.

Conclusion: Optimizing the Jaw Crusher correctly optimizes the entire stone quarry production line.

The jaw crusher is not only the core equipment of a stone crushing plant, but also a key factor affecting production efficiency, energy consumption, and equipment lifespan. By implementing the following measures:

Feed optimization

Parameter adjustment

Scientific maintenance

Automation systems

You can significantly improve jaw crusher efficiency, reduce downtime, and further enhance the profitability of the entire production line.

In summary, jaw crushers, with their efficient primary crushing capacity, robust structure, and optimization of subsequent processes, have become the foundation and core equipment for improving the overall production efficiency of stone crushing plants.

Want to learn more about improving jaw crusher performance?

Need a customized stone crushing plant solution?

Want to optimize jaw crusher throughput and reduce energy consumption?

Contact us for professional technical support and customized solutions.

Complete Guide to Sand Washing Machines: Working Principle and Industrial Sand Cleaning

2026-01-28 00:58How to Adjust Water Flow in a Sand Washing Machine: A Comprehensive Practical Guide

2026-01-23 01:29Sand Washing Machine Installation Guide: Step-by-Step Instructions for Optimal Performance

2026-01-15 06:46How Much Does a Sand Washing Machine Cost? A Practical Buyer’s Guide for 2026

2026-01-09 04:37Address: Luoyang Luoxin Industrial Park, Henan,China

E-mail: sales@yd-crusher.com

Phone: 86-139-3993-0123

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China