In the field of crushing equipment, jaw crushers and impact crushers are two of the most commonly used machines. Both play vital roles in mining,construction, and recycling industries, but they operate in very different ways and are suitable for different applications.

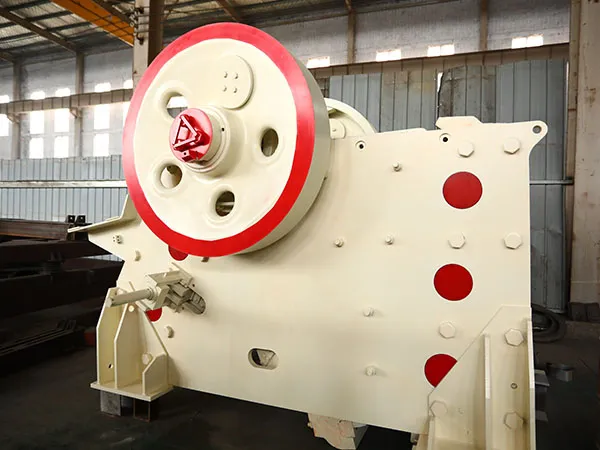

A jaw crusher is primarily designed for the first stage of crushing, handling large and hard materials such as granite, basalt, and ores. It works by compressing rocks between a fixed and a movable jaw plate, producing a more uniform and relatively coarse output.

On the other hand, an impact crusher is typically used for secondary or fine crushing.It reduces material size by using high-speed impact force, making it ideal for softer or medium-hard stones like limestone and concrete. The impact crusher produces more cubic-shaped particles,which are widely preferred in construction and road building.

A jaw crusher operates by compressing material between two jaws, one fixed and one movable. The material is fed into the top of the crushing chamber and is crushed as the movable jaw oscillates towards the fixed jaw.

The crushed material then falls through the bottom opening.

Key Characteristics:

Crushing Principle: Compression.

Material Suitability: Ideal for very hard, abrasive materials like granite, basalt, and various ores. They are known for their robustness and ability to handle tough, uncrushable materials.

Product Shape: Produces a more angular, flaky, and less uniform product.

Maintenance: Generally lower maintenance costs due to fewer wearing parts and simpler design.

Wear Parts: The main wear parts are the jaw plates, which are typically made from manganese steel.

Capacity: Can handle very large feed sizes.

Applications: Often used as primary crushers in mining, quarrying, and construction for initial size reduction.

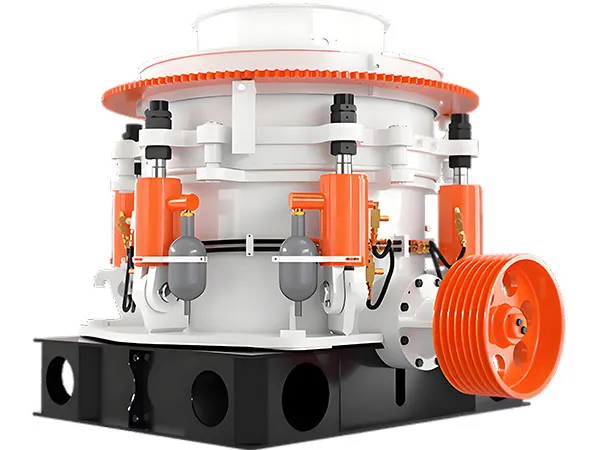

An impact crusher, also known as a hammer crusher, uses a different method to break down materials. It employs high-speed impact blows from hammers or blow bars attached to a rotor. The material is fed into the crusher and strikes these rapidly rotating hammers, which then throw the material against impact plates inside the crushing chamber. The repeated impacts cause the material to fracture and break.

Key Characteristics:

Crushing Principle: Impact and sometimes attrition (material rubbing against itself).

Material Suitability: Best suited for softer to medium-hard, non-abrasive materials like limestone, gypsum, and asphalt. They can also be used for recycling applications, such as crushing concrete and bricks.

Product Shape: Produces a more cubical, well-graded, and consistent product due to the multiple impact points. This cubical shape is often desirable in aggregate production.

Maintenance: Higher maintenance costs due to faster wear on the blow bars and impact plates, especially with abrasive materials.

Wear Parts: Blow bars (hammers) and impact plates are the primary wear parts, typically made of high-chrome steel or manganese steel.

Capacity: Can produce a higher reduction ratio in a single pass compared to jaw crushers.

Applications: Commonly used as primary or secondary crushers, particularly where the final product shape is important, such as in road construction and concrete aggregate production.

Jaw crushers and impact crushers are two of the most commonly used crushing equipment in the mining, quarrying, and construction industries. Although both machines are designed to break down large stones into smaller sizes, they operate on different principles and are suitable for different types of materials and applications.

In short, jaw crushers are preferred for strength and durability in handling hard materials, while impact crushers excel in shaping and producing finer aggregates for construction and road projects.

How to Adjust Water Flow in a Sand Washing Machine: A Comprehensive Practical Guide

2026-01-23 01:29Sand Washing Machine Installation Guide: Step-by-Step Instructions for Optimal Performance

2026-01-15 06:46How Much Does a Sand Washing Machine Cost? A Practical Buyer’s Guide for 2026

2026-01-09 04:37How Jaw Crushers Improve Efficiency in Stone Crushing Plants

2025-12-29 09:12Address: Luoyang Luoxin Industrial Park, Henan,China

E-mail: sales@yd-crusher.com

Phone: 86-139-3993-0123

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China