Cone crushers are indispensable equipment in industries such as mining, metallurgy, and construction, thanks to their superior crushing capacity and high productivity. Proper installation and operation are crucial to ensuring optimal performance, extending equipment life, and maximizing production efficiency. This article provides a detailed guide to cone crusher installation and operation, helping your business stand out in the competitive market.

Cone Crusher Performance Advantages

High Efficiency and Productivity:

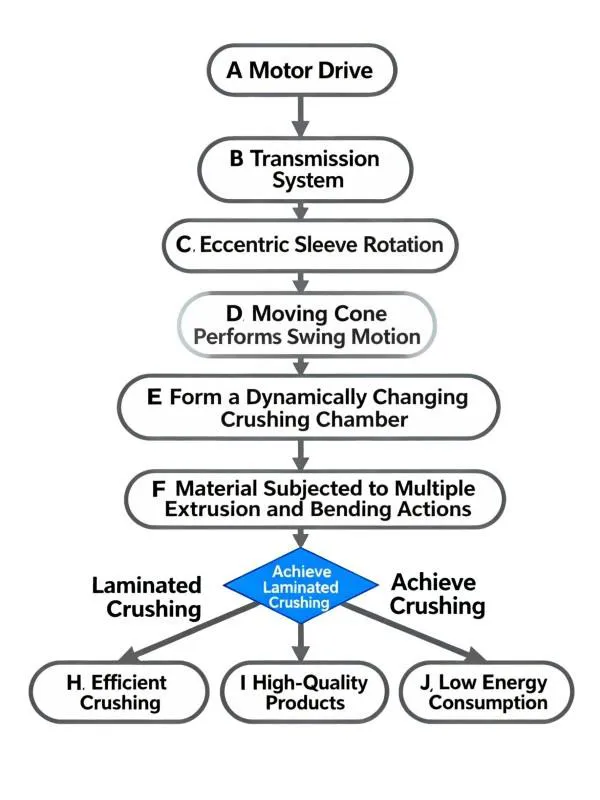

Using a continuous crushing principle, it offers a long working stroke, high processing capacity, and low energy consumption per ton (i.e., low energy consumption per ton).

The "laminated crushing" principle is its key feature. Material is squeezed and crushed between multiple layers of material, rather than through simple single-point impact, resulting in extremely high energy efficiency.

Excellent Product Shape:

The resulting material is primarily cubic with a low content of flakes. This is crucial for high-quality aggregate production, such as commercial concrete and asphalt pavement.

Stable Operation and Ease of Automation:

The discharge opening can be easily adjusted hydraulically or mechanically to control and adjust product particle size.

The hydraulic system also provides over-iron protection and cavity clearing functions, significantly reducing downtime and facilitating integration into automated production lines.

Reliable Lubrication System:

An independent thin oil lubrication station provides forced lubrication and cooling for critical components, such as the main bearing, ensuring long-term, stable operation under heavy loads.

The installation of a cone crusher is a critical first step in the entire equipment lifecycle, directly impacting its stability and subsequent operational efficiency. As a professional cone crusher manufacturer, Yutech recommends that when installing a cone crusher, you first understand its structure to ensure proper installation and maximize crushing efficiency.

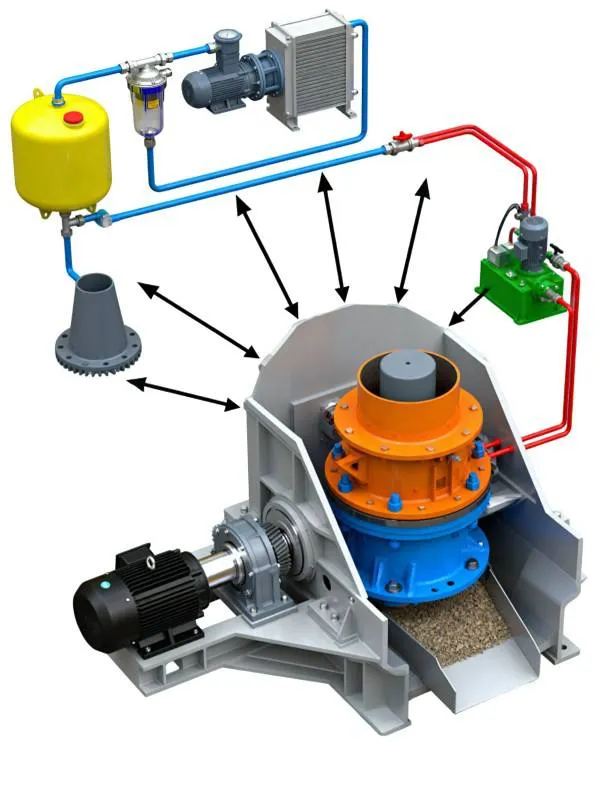

Cone Crusher Structure

1. Site Selection and Foundation:

Site Considerations: The crusher should be installed in an open area away from residential areas with good ventilation and drainage. Material transportation routes should also be considered to ensure convenient and efficient transportation.

Foundation Requirements: The foundation must be strong and flat, capable of supporting the full weight of the crusher and its contents. The foundation should be constructed of reinforced concrete and have pre-set anchor bolt holes. The foundation depth and dimensions must be strictly adhered to the crusher model and manufacturer's specifications.

2. Equipment Positioning and Leveling:

Lifting: Use appropriate lifting equipment to smoothly lift the crusher main unit onto the foundation, ensuring alignment with the anchor bolt holes.

Leveling: Use a spirit level to carefully check the crusher's levelness. Adjust the shims under the base to ensure the equipment is perfectly level. An unstable installation will cause excessive vibration, affecting its performance and lifespan.

3. Fastening and Connections:

Anchor Bolts: Tighten all anchor bolts evenly and gradually to ensure a secure connection between the crusher and the foundation. Regularly check levelness during tightening.

Drive: Install the drive belt or coupling, ensuring it is properly tightened and correctly aligned.

Lubrication System: Connect the lubricating oil lines and ensure they are properly sealed and leak-free. Add the appropriate lubricant according to the manufacturer's specifications.

4. Electrical Connections:

Power Connection: Have a professional electrician perform the power connection and ensure that the wiring complies with national electrical safety standards.

Control System: Connect the control cabinet and sensors, perform necessary wiring checks, and ensure that all electrical components are functioning properly.

Correct operating procedures not only ensure production safety but also maximize the performance of the cone crusher and reduce operating costs.

Cone Crusher Working Principle

Understanding the structure and working principle of the cone crusher lays the foundation for subsequent operations, enabling safer and more proficient operation.

1. Pre-Startup Inspection:

External Inspection: Confirm that all protective covers and safety devices are in place and not loose.

Lubrication System: Check the oil level and lubricating oil for cleanliness. Ensure the cooling water system is functioning properly.

Fasteners: Check that all bolts are tight, especially those in key areas such as the mainshaft bushing and gears.

Crushing Chamber: Verify that the crushing chamber is free of debris, especially metal or other non-crushable materials.

Test Run: Perform a short test run under no-load conditions to inspect the motor, transmission components, lubrication system, and cooling system for any abnormal sounds or vibrations.

2. Production Operation:

Uniform Feeding: Ensure that material is fed evenly and continuously into the crushing chamber, avoiding large, simultaneous or intermittent feeding. Excessive feed rates can easily cause blockage and overload, while insufficient feed rates can affect production efficiency.

Discharge Opening Adjustment: Adjust the discharge opening size appropriately based on the desired product size. Follow the manufacturer's instructions when making adjustments and avoid making adjustments while the crusher is under load.

Monitoring Operational Status: Closely monitor equipment parameters such as current, voltage, oil temperature, oil pressure, and vibration. If any abnormalities are detected, immediately stop the machine for inspection and troubleshooting.

Dust Control: Cone crushers generate significant amounts of dust during operation. An effective dust removal system should be installed to protect operator health and the surrounding environment.

3. Shutdown and Maintenance:

Normal Shutdown: Before shutting down, stop feeding and wait until all material in the crushing chamber is completely discharged before shutting down the main unit.

Lubrication: Regularly check and replace lubricating oil and grease to ensure adequate lubrication of all lubrication points.

Wear Parts: Regularly check the wear of vulnerable parts such as the mortar wall and crushing wall, and replace them promptly to prevent excessive wear that affects crushing efficiency or damages the main unit.

Fasteners: Regularly check the tightness of all bolts to prevent loosening that could lead to equipment failure.

Cleaning: Regularly clean dust and debris from the exterior and interior of the equipment.

Periodic Maintenance: Perform periodic overhauls and maintenance according to the manufacturer's recommendations, conduct a comprehensive inspection and maintenance of the equipment, and replace aging parts to ensure the equipment is always in good working condition.

This concludes the complete introduction to the correct installation and standard operation of cone crushers. Proper installation and standard operation are the fundamental guarantee for their efficient and stable operation. Companies should prioritize employee training to ensure operators possess professional knowledge and skills. By following the recommendations in this guide, your cone crusher will operate more safely and efficiently, delivering significant economic benefits to your production. Continuously monitoring equipment operating conditions and strictly adhering to maintenance plans are key to extending equipment life and reducing operating costs. If you encounter any installation or operational issues, please contact us and we will provide professional technical support.

How to Replace Cone Crusher Bronze Bushings Correctly: A Complete Step-by-Step Guide

2026-03-05 04:48Impact Crusher Price Guide: Understanding the Real Factors Behind Your Investment Costs

2026-02-25 01:28Complete Guide to Sand Washing Machines: Working Principle and Industrial Sand Cleaning

2026-01-28 00:58How to Adjust Water Flow in a Sand Washing Machine: A Comprehensive Practical Guide

2026-01-23 01:29Address: Luoyang Luoxin Industrial Park, Henan,China

E-mail: sales@yd-crusher.com

Phone: 86-139-3993-0123

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China