The capacity of a jaw crusher is usually measured in tons per hour (tph), but this is not a fixed figure. It is a dynamic variable and is affected by a combination of factors related to the material crushed, crusher design and operating parameters, and maintenance practices.Understanding these factors is critical to optimizing crusher performance and overall plant efficiency.

Hardness and Abrasiveness:

Hardness: Harder materials require more energy to crush and can significantly reduce the crushing speed, thus lowering capacity.

Abrasiveness: Highly abrasive materials cause faster wear on jaw plates and other crushing parts. Increased wear leads to reduced efficiency and necessitates more frequent replacements, resulting in downtime and lower overall capacity.

Humidity/Moisture Content:

Materials with high moisture content (especially "inner moisture" absorbed by the rock, not just surface water) can become sticky or "clay-like," leading to clogging and bridging in the crushing chamber. This impedes material flow and reduces throughput.

Composition and Particle Size Distribution of Feed:

Fines Content: Excessive fines (powder) in the raw material can hinder crushing by filling voids in the chamber, reducing the efficiency of the crushing action, and potentially causing adhesion issues. Screening out fines before crushing can improve capacity.

Maximum Feed Size: The size of the material fed into the crusher directly impacts capacity. If feed material is too large relative to the crusher's gape (feed opening), it can cause bridging (material blocking the opening) and halt production. Jaw crushers are typically sized so that the maximum feed size is around 80% of the gape.

Viscosity: Materials with high viscosity are more prone to sticking and clogging, similar to high humidity.

Bulk Density: The bulk density of the material affects the volumetric capacity when converting to mass capacity (tons).

Closed Side Setting (CSS) / Discharge Opening:

The CSS is the smallest gap between the fixed and movable jaw plates. A smaller CSS produces a finer product but generally reduces the crushing capacity as it restricts material flow. A larger CSS allows for higher capacity but produces a coarser product.

Nip Angle:

This is the angle between the fixed and movable jaw plates. An optimal nip angle (typically between 18°-20°, less than 25°) ensures effective crushing. If the angle is too large, material can "kick back" or be squeezed out of the cavity, reducing crushing efficiency and potentially being dangerous.

Eccentric Shaft Revolutions (Speed):

Within a certain range, increasing the eccentric shaft's RPM (revolutions per minute) can improve capacity by increasing the number of crushing cycles. However, if the speed is too high, the material may not have enough time to be discharged, leading to blockages and reduced capacity.

Jaw Plate Profile and Condition:

The design and wear condition of the jaw plates significantly impact crushing performance. An appropriate jaw die profile (e.g., toothed for flaky rock) can optimize production and reduce bridging. Worn jaw plates can lead to increased crushing angles, loss of tooth profile, and reduced efficiency, directly impacting capacity.

Regular monitoring and rotation/replacement of worn parts are crucial.

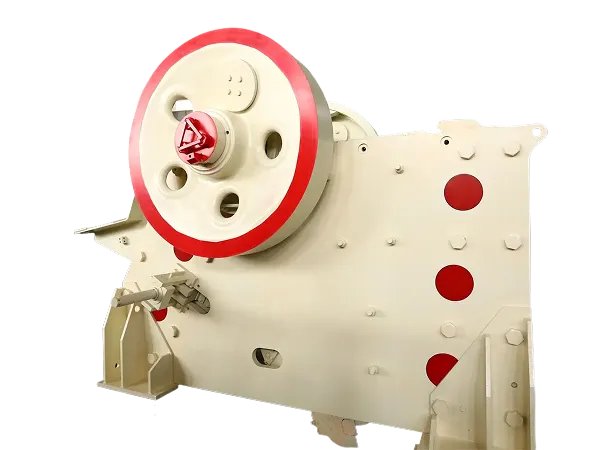

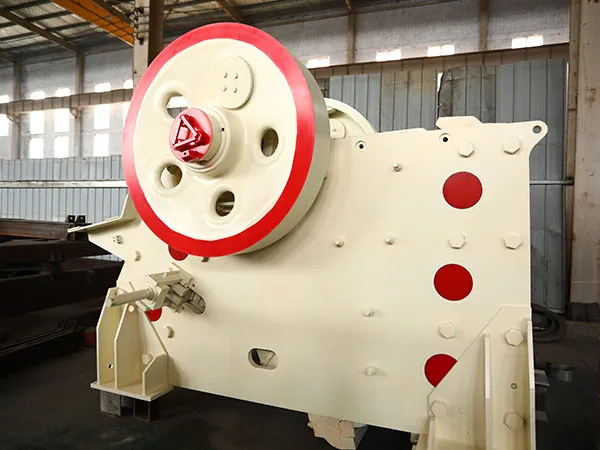

Jaw Crusher Type and Size:

Larger jaw crushers generally have higher capacities. Different designs (e.g., single-toggle vs. double-toggle) can also have varying characteristics that influence throughput.

Crushing Chamber Optimization:

Modifying the shape of the movable jaw plate or optimizing the crushing cavity design can improve discharge capacity and overall production.

Throw of the Machine:

The throw, or the distance the movable jaw travels, impacts the effectiveness of crushing and the compaction of the product.

Consistent and Controlled Feeding:

A continuous and uniform feed rate, without over- or under-feeding, is essential for optimal capacity. Intermittent feeding or surges can reduce efficiency.

Proper feeding methods, often using vibrating grizzly feeders or scalping screens, help remove fines and ensure the correct maximum feed size enters the crusher.

Maintenance and Wear Part Management:

Regular lubrication and maintenance of wear-resistant parts (jaw plates, eccentric shaft, connecting rod, etc.) are critical. Timely repair or replacement of worn parts prevents significant drops in capacity and avoids costly breakdowns.

Monitoring jaw wear and rotating or replacing plates at the optimal time can prevent a 10-20% reduction in production.

Tramp Metal Relief:

Systems that allow uncrushable materials (tramp metal) to pass through without damaging the crusher help prevent downtime and maintain continuous operation.

Operator Skill and Monitoring:

Experienced operators who can monitor material flow, identify bridging, and make necessary adjustments to the feed rate or CSS can significantly impact a jaw crusher's output.

In conclusion, maximizing jaw crusher capacity is about finding the optimal balance between all these factors to suit the specific material and desired final product.

Complete Guide to Sand Washing Machines: Working Principle and Industrial Sand Cleaning

2026-01-28 00:58How to Adjust Water Flow in a Sand Washing Machine: A Comprehensive Practical Guide

2026-01-23 01:29Sand Washing Machine Installation Guide: Step-by-Step Instructions for Optimal Performance

2026-01-15 06:46How Much Does a Sand Washing Machine Cost? A Practical Buyer’s Guide for 2026

2026-01-09 04:37Address: Luoyang Luoxin Industrial Park, Henan,China

E-mail: sales@yd-crusher.com

Phone: 86-139-3993-0123

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China