Circular vibrating screen working principle

The motor makes the eccentric shaft of the exciter rotate at a high speed through the triangle belt or flexible coupling. The running eccentric shaft generates a great centrifugal force, which excites the screen box to produce a certain amplitude of circular motion, and the materials on the screen are subjected to the impulse transmitted by the screen box on the tilted screen surface to produce a continuous throwing motion, and the materials are stratified in the process of throwing up, and the particles which are smaller than the screen holes are screened through the screen in the process of meeting with the screen surface, so as to realize the grading.

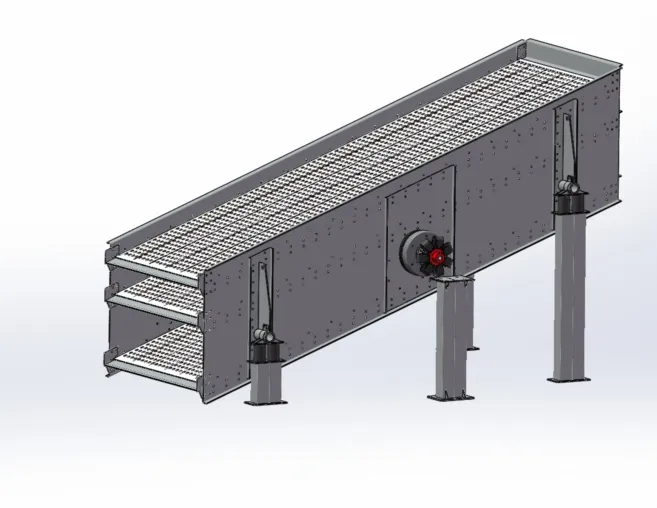

Circular vibrating screen structure composition

Circular vibrating screen sifter is mainly composed of screen box, screen mesh, vibrator, vibration damping spring device, chassis, etc. It adopts cylinder eccentric shaft exciter and bias block to adjust the amplitude. Adopting cylinder eccentric shaft exciter and partial block to adjust the amplitude, the vibrator is installed on the side plate of the screen box, and driven by the motor through the triangular belt or flexible coupling to rotate, generating centrifugal inertia force, forcing the screen box to vibrate. The side plate of the screen machine is made of high quality steel plate, and the side plate is connected with the crossbeam and the base of the vibrator by high-strength bolts or ring groove rivets.

Circular vibrating screen structure characteristics

1. Adopting shaft eccentricity supplemented by block eccentricity as the excitation force, the excitation force is strong and easy to be adjusted; 2. The sieve beam and the sieve box are connected by high-strength bolts, without welding;

3. The sieve machine structure is simple, easy and quick maintenance;

4. Adopting tire coupling, flexible coupling, stable operation;

5. High screening efficiency, large handling capacity and long service life.

YK (R) series circular vibrating screen main technical parameters

|

Model Specification

|

Number of screen layers

|

Sieve surface inclination (°)

|

Screen area (m²)

|

Vibration frequency (r/min)

|

Double amplitude (mm)

|

Treatment capacity (t/h)

|

Motor power (kW)

|

Overall dimensions (L×W×H) (mm)

|

|

2YK(R)1860

|

2

|

20

|

10.8

|

740

|

6-8

|

45-480

|

11-8

|

5706×2524×4343

|

|

3YK(R)1860

|

3

|

20

|

10.8

|

740

|

6-8

|

45-480

|

15-8

|

5706×2524×4646

|

|

4YK(R)1860

|

4

|

20

|

10.8

|

740

|

6-8

|

45-480

|

15-8

|

5620×2524×4946

|

|

2YK(R)2160

|

2

|

20

|

12.6

|

740

|

6-8

|

90-800

|

18.5-8

|

5706×2824×4343

|

|

3YK(R)2160

|

3

|

20

|

12.6

|

740

|

6-8

|

90-800

|

22-8

|

5706×2824×4646

|

|

4YK(R)2160

|

4

|

20

|

12.6

|

740

|

6-8

|

90-800

|

30-8

|

5620×2824×4946

|

|

2YK(R)2460

|

2

|

20

|

14.4

|

740

|

6-8

|

130-860

|

22-8

|

5706×3124×4343

|

|

3YK(R)2460

|

3

|

20

|

14.4

|

740

|

6-8

|

130-860

|

30-8

|

5706×3124×4646

|

|

4YK(R)2460

|

4

|

20

|

14.4

|

740

|

6-8

|

130-860

|

37-8

|

5620×3124×4946

|

|

2YK(R)2470

|

2

|

20

|

16.8

|

740

|

6-8

|

150-900

|

30-8

|

6620*3124*4288

|

|

3YK(R)2470

|

3

|

20

|

16.8

|

740

|

6-8

|

150-900

|

37-8

|

6639*3124*4647

|

|

2YK(R)2573

|

2

|

20

|

18.2

|

740

|

6-8

|

140-900

|

30-8

|

6920×3224×4343

|

|

3YK(R)2573

|

3

|

20

|

18.2

|

740

|

6-8

|

140-900

|

37-8

|

6920×3224×4646

|

|

4YK(R)2573

|

4

|

20

|

18.2

|

740

|

6-8

|

140-900

|

37-8

|

6920×3224×4946

|

|

2YK(R)2773

|

2

|

20

|

19.7

|

740

|

6-8

|

170-1000

|

30-8

|

6920×3424×4343

|

|

3YK(R)2773

|

3

|

20

|

19.7

|

740

|

6-8

|

170-1000

|

37-8

|

6920×3424×4646

|

|

4YK(R)2773

|

4

|

20

|

19.7

|

740

|

6-8

|

170-1000

|

37-8

|

6920×3424×4946

|

|

2YK(R)3073

|

2

|

20

|

21.9

|

740

|

6-8

|

200-1100

|

30-8

|

6920×3724×4343

|

|

3YK(R)3073

|

3

|

20

|

21.9

|

740

|

6-8

|

200-1100

|

37-8

|

6920×3724×4646

|

|

4YK(R)3073

|

4

|

20

|

21.9

|

740

|

6-8

|

200-1100

|

37-8

|

6920×3724×4946

|

Circular vibrating screen installation and commissioning

1. Articulation chute:

Sieve inlet and discharge chute, sieve discharge hopper and sieve box to maintain a minimum clearance of 40 mm, in order to make full use of the effective area of the sieve work, the inlet chute should make the material uniformly distributed over the entire width of the sieve, at the same time make the material into the sieve of the initial velocity is reduced to a minimum, in order to prevent the material from impacting the damage to the sieve surface, the inlet chute mouth to the sieve surface of the vertical drop should be no more than 200 mm.

2. Installation:

The installation of the sieve at the use site should meet the requirements of the general drawing, and the installation order is as follows:

(1) Level the foundation first, then install the bracket and motor frame, adjust the relative position and fix it initially, then install the vibration-damping springs in turn, and the stiffness of each spring, especially the spring stiffness at the left and right symmetry points, should be matched consistently.

(2) Install the sieve: transport the sieve to the installation place, lift and make the inclination angle of the sieve surface meet the requirements of the general drawing, and then slowly lower it down, and it should fall on the vibration-damping spring.

(3) Check the downward pressure of each support spring to ensure that the height difference between the front and rear ends and the left and right ends of the spring is not more than 2mm.

(4) Install and wire the motor, and pay attention to the correct direction of motor rotation when wiring.

(5) Check the relative position of screen box and chute, sieve funnel, to ensure that there is a 40mm working clearance to eliminate the possibility of collision.

(6) Check the tightness of all the bolts.

(7) Check the degree of flexibility of the shaker, rotate the eccentric wheel by hand to make the eccentric out of balance position, there should be several free swing, such as sieve arrival time more than half a year before installation, the shaker should be re-cleaned and oil change.

(8) Install the flexible coupling between the shaker and the motor, pay attention to make the motor axis coaxial with the vibrator axis.

3. Test run and acceptance:

(1) After installing and checking according to the foregoing, the sieve can be empty for test run;

(2) Test run (empty) not less than 4 hours, in the test run time should be constantly observed sieve, sieve start should be smooth, rapid, stable vibration, no special noise.

(3) No oil leakage.

(4) The sieve can be measured after normal operation of process parameters.

A. Through the amplitude observation sieve amplitude should meet the requirements;

B. The maximum temperature of the exciter bearing shall not exceed 85℃.

Circular vibrating screen use and maintenance

1. Process

The vibrating screen should be started without material on the screen surface, try to avoid starting the machine with material, and the material can only be fed after the screen machine runs smoothly. Before stopping the machine, it should stop feeding first, and then stop the machine after the surface material is excluded. During the working process, the operation of the sieve machine should be frequently observed, if abnormal movement or abnormal sound is found, it should be promptly shut down for inspection, to find out the reasons and troubleshooting.

2. Amplitude adjustment

This series of equipment by changing the exciter on both sides of the eccentric block thickness or number of amplitude adjustment. Adjustment must ensure that the number and thickness of the eccentric blocks at both ends are completely symmetrical.

3. Bearing lubrication

This series of equipment using rare lubrication, lubricant grade: L-HM46 GB11118.1-2011, the amount of oil should be

Add to the oil mark above the median line. Generally replenish once a week, the first oil change must be changed within 2 months, and then replace the new oil once every six months. The oil quantity required for replacing new oil of various models of vibrating screen can refer to the following table.

Vibrating screen lubricating oil quantity list

|

Vibrating screen model

|

2YK(R)1860 3YK(R)1860 4YK(R)1860

|

2YK(R)2160 3YK(R)2160 4YK(R)2160

|

2YK(R)2460 3YK(R)2460 4YK(R)2460

|

2YK(R)2573 3YK(R)2573 4YK(R)2573

|

2YK(R)2773 3YK(R)2773 4YK(R)2773

|

2YK(R)3073 3YK(R)3073 4YK(R)3073

|

|

Oil volume(KG)

|

13KG

|

16KG

|

19KG

|

20KG

|

22KG

|

25KG

|

Common faults and measures to deal with them

|

Fault Phenomenon

|

Main Reasons

|

Treatment

|

|

Sieve box torsion vibration, transverse swing

|

1. The size or phase of the eccentric blocks on both sides of the shaker is inconsistent;

2. The four corners of the support spring stiffness difference.

|

1. Adjust the eccentric blocks on both sides to make them completely symmetrical;

2. Select and match the supporting spring to make its stiffness consistent.

|

|

Uneven vibration of the sieve box, the material layer on the sieve is too thick.

|

1. The sieve hole is blocked;

2. Uneven feeding, too much large materials;

3. Damage to the support spring;

4. Small angle of inclination of screen surface.

|

1. Clean the screen;

2. Adjust the feeding amount and feeding material degree, uniform feeding;

3. Replace the spring;

4. Adjust the angle of inclination of the screen surface.

|

|

Bearing overheating

|

1. Bearing oil shortage;

2. Bearing damage;

3. Small bearing clearance or improper assembly.

|

1. Add enough oil;

2. Replace the bearing;

3. Change to large clearance bearing or reinstallation.

|

|

The screen surface breaks and wears out too quickly

|

1. The rubber gasket is damaged;

2. he screen is not pressed tightly and evenly;

3. Uneven feeding along the width direction, too much large materials.

|

1. Replace the gasket;

2. Re-press and even out the screen mesh;

3. Adjust the feeding method and position, control the feeding granularity.

|

|

abnormal noise

|

1. Damaged bearings;

2. Loose sieve box bolts.

|

1. Replace the bearings;

2. Tighten bolts.

|