The operation can be broken down into two main functions: the crushing action and the hydraulic control.

1. The Crushing Action (Laminated Crushing):

The electric motor drives the eccentric sleeve, causing it to rotate at high speed around the stationary main shaft.

This rotation imparts a gyrating motion to the mantle. The mantle does not spin; it oscillates in a circular path.

Material fed into the top of the crushing chamber falls between the mantle and the concave.

On one side of the chamber, the mantle moves towards the concave, squeezing and crushing the material.

Simultaneously, on the opposite side, the mantle moves away from the concave, allowing the crushed material to fall further down into the chamber.

This process continues as the material moves down through the progressively narrowing chamber until it is small enough to exit at the bottom. This method, known as laminated (or inter-particle) crushing, where rocks are crushed against each other, produces a high-quality, cubical product shape.

2. The Role of the Hydraulic System:

This is what makes the multi-cylinder design so effective.

Setting Adjustment (CSS - Closed Side Setting):

The Closed Side Setting is the narrowest gap between the mantle and the concave at the bottom of the crushing chamber. It determines the final product size.

To adjust the CSS, the operator uses the hydraulic system. The cylinders extend or retract in unison, precisely lifting or lowering the entire bowl assembly. This changes the gap quickly and easily, often via a simple push-button or PLC control, even while the crusher is running.

Overload Protection (Tramp Release):

Inevitably, uncrushable material like a piece of steel (tramp iron) may enter the crusher. In a less advanced machine, this could cause catastrophic damage.

In a multi-cylinder crusher, the hydraulic cylinders are held at a set pressure. If tramp iron enters, the crushing force spikes dramatically, exceeding this pre-set hydraulic pressure.

The cylinders automatically retract, allowing the bowl to lift up and the uncrushable object to pass through the chamber safely.

Once the object is cleared, the cylinders automatically return the bowl to its original CSS setting, and crushing resumes with minimal downtime.

Advantages of the Multi-Cylinder Design

High Crushing Efficiency & Capacity: The combination of high speed, large crushing stroke, and optimized chamber design leads to very high throughput.

Excellent Product Shape: The laminated crushing principle produces a superior, cubical-shaped aggregate, which is highly desirable for concrete and asphalt production.

Superior and Reliable Overload Protection: The hydraulic tramp release system is far more effective and reliable than the older spring-based systems, preventing costly damage and downtime.

Easy and Precise Adjustment: The ability to adjust the CSS hydraulically from a control panel saves significant time and labor compared to manual or mechanical adjustments.

High Automation: These crushers are easily integrated into a modern, automated plant control system (PLC), allowing for remote monitoring and adjustment.

Structural Integrity: The fixed main shaft design provides a very strong and stable structure, capable of handling high crushing forces. The even distribution of force across multiple cylinders further enhances stability.

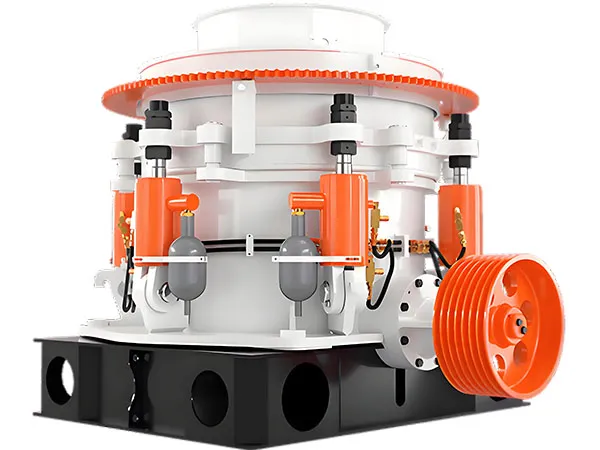

The multi-cylinder hydraulic cone crusher is a high-performance crushing equipment designed for medium to fine crushing operations in mining, quarrying, and aggregate production. It is renowned for its advanced structure, high crushing efficiency, and excellent automation features.

This crusher integrates a number of cylinders, each controlled by an independent hydraulic system, which provides enhanced crushing force, better overload protection, and more precise control over discharge size. Its optimized design ensures uniform product granularity, reduced downtime, and extended service life of components.

Key Components

Main Frame: The robust foundation of the crusher that supports all other components.

Stationary Main Shaft: Unlike some designs, the main shaft in a multi-cylinder crusher is typically fixed. This provides greater strength and stability.

Eccentric Sleeve: A sleeve that rotates around the fixed main shaft. Its internal bore is offset, creating an eccentric (gyrating) motion.

Mantle (Moving Cone): A cone-shaped wear part mounted on the main crushing head. It gyrates within the bowl, driven by the eccentric sleeve.

Bowl & Concave (Stationary Cone): The upper part of the crusher that contains the concave (or bowl liner). The concave is the stationary wear part against which the material is crushed.

Hydraulic Cylinders: These are the heart of the machine's control system. They are used to lift and lower the bowl assembly to adjust the gap and to provide a pressure-relief system.

Hydraulic Power Unit: An external unit containing the oil reservoir, pumps, valves, and accumulators that power and control the hydraulic cylinders.

Drive System: An electric motor, V-belts, and a countershaft assembly that transmit power to the eccentric sleeve.

Lubrication System: A dedicated system to supply oil to the internal gearing and bearings, ensuring smooth operation and preventing overheating.